A dual line grease distributor, also known as a dual line lubrication system ,The principle of operation of the two-line system consists of two half-cycles.It is a type of centralized lubrication system used to distribute grease or oil to various lubrication points in machinery or equipment. In the first half-cycle, the lubricant is pumped to the main line (A), which is connected to the exhaust line (B). Afterwards, the lubricant is channelled through a changeover valve to a dispensing valve.It is commonly used in industrial applications where multiple lubrication points need to be serviced simultaneously.

The basic principle of a dual line grease distributor involves the use of two main lines that supply lubricant to the lubrication points. Here’s how it works:

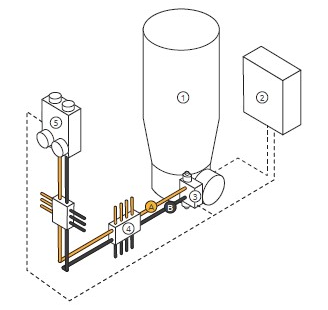

Lubricant Supply: The system consists of a central pump or lubricant reservoir that stores the grease or oil. This pump is responsible for supplying the lubricant to the system This pump is responsible for supplying the lubricant to the system In clude support and storage components.

Main Lines: From the pump, two main lines, often referred to as the “primary” and “secondary” lines, are connected. These lines are typically made of steel tubing or flexible hoses and are routed throughout the machinery or equipment.

Pistons or Distributors: At each lubrication point, there is a piston or distributor unit. These units are mounted on the machinery and connected to the main lines. They are responsible for controlling the flow of lubricant to the lubrication points.The downward movement of the pilot piston 4a connects the upper chamber of the main piston 4b with the upper chamber of the pilot piston, and the lower chamber of the main piston with the oil outlet, and the lubricant supplied and delivered enters the upper chamber of the main piston, pushes the main piston downward, and presses the lubricant in the lower chamber of the main piston through the oil feed tube 6 to the lubrication point, and completes the first cycle of the oil feeding action.

Operation: The system operates in cycles, alternating between the primary and secondary lines. When the system is activated, the pump pressurizes one of the main lines (for example, the primary line) while the other line (secondary line) is depressurized.

Lubricant Distribution: As the primary line is pressurized, the pistons or distributors connected to that line are also pressurized. This causes the pistons or distributors to move and distribute the lubricant to the lubrication points.The dispenser piston performs the preceding actions in the same order and in reverse..

Reversal: After a predetermined time or stroke count, the system reverses the cycle. The pump switches to pressurizing the secondary line while the primary line is depressurized. This reversal ensures that lubricant is distributed evenly to all lubrication points over time.

In addition, the distributor piston two-end screw plug is not allowed to dismantle for no reason, such as leakage should be tightened or replaced with a new sealing washer, and the distributor contact surface should be smooth and flat, the mounting bolts should not be tightened too tightly, so as not to deform the impact of the normal action, in the dusty, humid, harsh environments, should be equipped with a protective cover, and must be in the specified environment using the prescribed medium.

Post time: Oct-16-2023