Electric grease pumps, also known as electric lubrication systems, are designed to

efficiently and effectively distribute grease to various lubrication points in machinery and

equipment. Their efficiency can be evaluated based on several factors:

- Flow Rate: The flow rate of an electric grease pump determines how much grease it

- can deliver per unit of time. Higher flow rates allow for faster lubrication, reducing

- downtime and increasing productivity. Efficient electric grease pumps have sufficient

- flow rates to meet the lubrication requirements of the equipment they are servicing.

- Pressure Capability: Electric grease pumps should be capable of generating

- sufficient pressure to deliver grease to all the lubrication points effectively. Adequate

- pressure ensures that the grease reaches the required areas and provides proper

- lubrication. An efficient pump will maintain consistent pressure throughout the

- lubrication process.

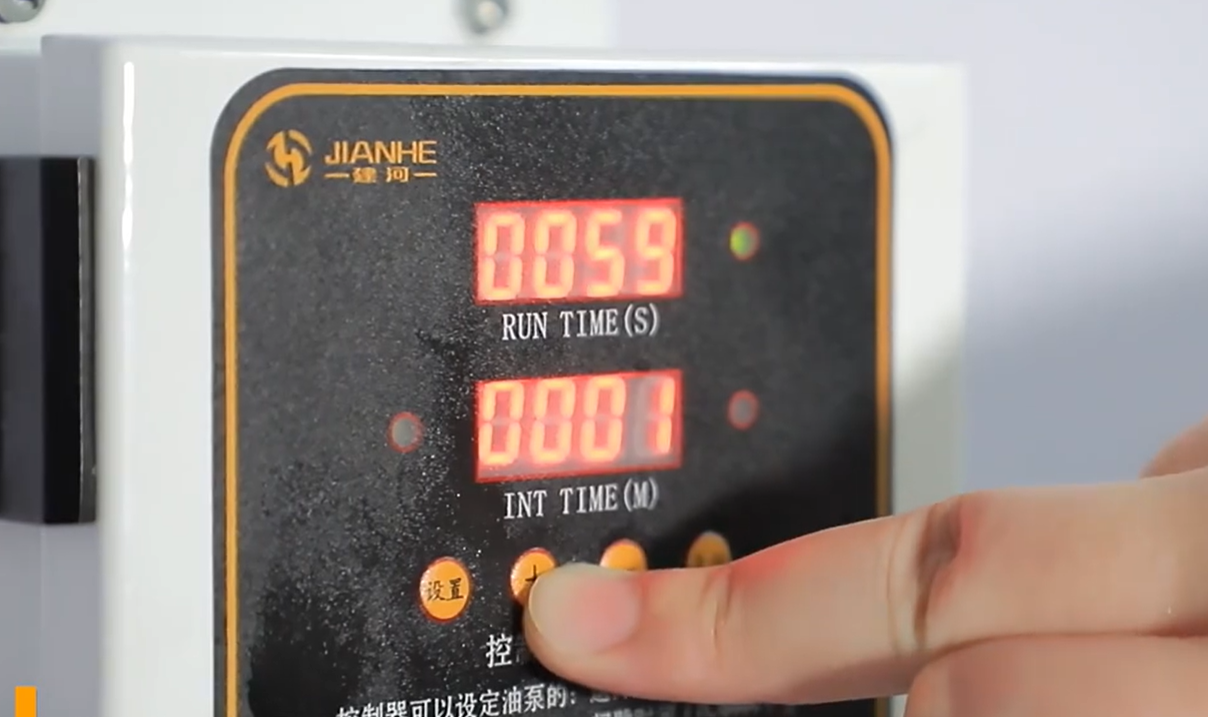

- Control and Monitoring: Electric grease pumps with advanced control and

- monitoring features enhance efficiency. These features may include programmable

- settings, timers, and sensors that allow precise control over the lubrication process.

- Monitoring capabilities can provide real-time feedback on grease levels, pressure, and

- system performance, enabling proactive maintenance and reducing the risk of

- equipment failure.

- Reliability and Maintenance: An efficient electric grease pump should be reliable

- and require minimal maintenance. High-quality pumps with durable components and

- seals can operate consistently without frequent breakdowns or the need for extensive

- servicing. Easy access to service and maintenance points, such as filters and fittings,

- can also contribute to overall efficiency.

- Energy Efficiency: Electric grease pumps that are designed with energy efficiency in

- mind can help reduce operational costs. Energy-saving features, such as variable speed

- drives or efficient motor designs, can optimize power consumption and minimize waste.

It’s important to note that the efficiency of an electric grease pump also depends on the

proper selection and application of the grease itself. Using the correct type and amount of

grease, as recommended by the equipment manufacturer, ensures optimal lubrication and

further enhances the overall efficiency of the system.

Post time: Oct-10-2023