Today, I will show you the necessity of popular science lubrication. How to maintain lubrication equipment. Friction and wear are one of the three main forms of damage to mechanical parts; it is a main reason for reducing the efficiency, accuracy and even scrapping of machines and tools. Therefore, it is very important to lubricate the machine.

Lubrication is a means of adding a substance with lubricating properties to the friction surface of two objects in contact with each other to reduce friction and wear. Commonly used lubricating media are lubricating oil and grease. The advantages of the oil lubrication method are: the oil has good fluidity, good cooling effect, easy to filter to remove impurities, can be used for lubrication in all speed ranges, has a long service life, is easy to replace, and the oil can be recycled. The grease is mostly used in low and medium speed machinery.

In short, in the lubrication work, the choice of lubrication methods and devices must be based on the actual conditions of the mechanical equipment, that is, the structure of the equipment, the motion form of the friction pair, the speed, the load, the degree of precision, and the working environment.

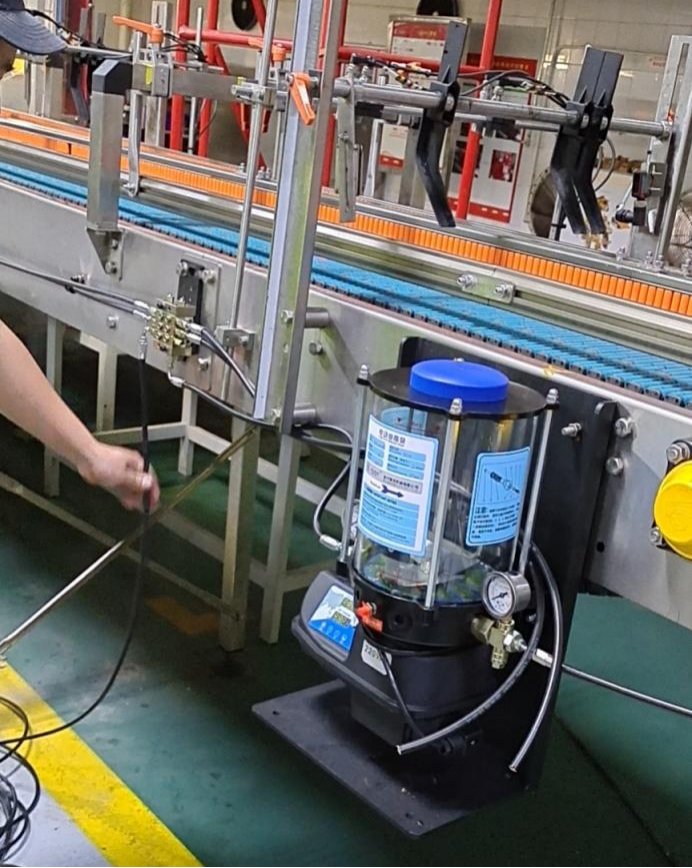

The lubrication pump can conveniently lubricate the machine, which can improve friction, reduce friction, prevent wear, and reduce power consumption. Moreover, most of the heat generated by the machine during friction is taken away by the lubricating oil, and a small part of the heat is directly dissipated through conductive radiation. At the same time, the friction piece moves on the oil film, as if floating on the "oil pillow", which has a certain buffering effect on the vibration of the equipment. It can also protect against corrosion and dust.

Regarding the daily maintenance of equipment lubrication, we need to check the oil level and oil level of the equipment before the equipment starts operation, carry out daily refueling to start the lubrication system, and confirm that the system is working well, the oil path is unobstructed, the oil level is eye-catching, and the pressure meets the requirements. Check whether the pressure meets the regulations at any time during the class. Taking steam turbine oil as an example, attention should be paid during use: ①Try to prevent gas leakage, water leakage, and electric leakage of the steam turbine unit; ②Control the oil return temperature below 65°C; ③The oil tank regularly cuts water and releases impurities to keep the oil clean Pollution of water, rust, sediment, etc.

Post time: Oct-16-2021